ABB Collaborative Robot Application Builder

Published by Carolina Motion Controls, Inc. on 12th Mar 2024

ABB Cobot Application Builder

Simulate Applications for ABB's Line of Cobots

The ABB Collaborative Robot Application Builder allows simulate different applications for their line of collaborative robots. First, you can pick from the GoFa, SWIFTI, dual-arm YuMi, and single-arm YuMi. You can then pick which application you would like to simulate along with the mounting style, end of arm tooling, infeed, outfeed, and accessories. Once you have all of these options picked out, you can press play and it will you a short simulated video of how it may look. Below are a few examples.

|  |

|

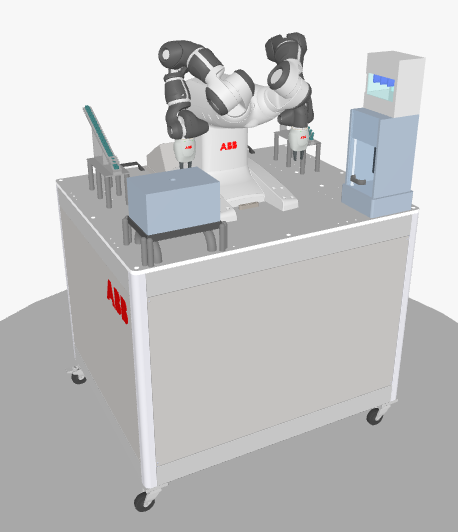

In the first example, I chose a dual-arm YuMi as the cobot. It is set up for small parts assembly, and it's table mounted with a servo gripper. I also chose a fixed position infeed (the magazine style ramp) so that there is no vision system required. The robot simply reaches to the exact same position each time to grab a new part. Finally, I chose a fixed position outfeed for the same reason.

The second example is the SWIFTI cobot which is set up for part handling. The cobot is ceiling mounted with a vacuum for the end of arm tooling. The infeed is a smart shaker table with a vision system. The shaker table receives components from a conveyer belt then shakes them in order to lay them out in an easy orientation for the cobot. The vision system then takes a picture of the layout so that the cobot knows where they are. I then selected a tray pattern outfeed. Once this tray is full, the SWIFTI with halt operations until either a person or another robot picks it up and replaces it with an empty tray. Finally, I chose a laser scanner as an accessory. Since the SWIFTI is much faster than the other cobots, it requires more safety measures. You may notice the red area on the floor. This represents the area where if something is detected, the robot will stop operations.

The final example is a GoFa set up for machine tending. This cobot is table mounted with a servo gripper for the end of arm tooling. I chose the fixed position tray for both the infeed and the outfeed. Once the outfeed is full, either an operator or another robot will take it away and replace it with an empty one. The fixed position makes it easier for the robot since it has no vision system.

-2_1670261595__49352.original.png)