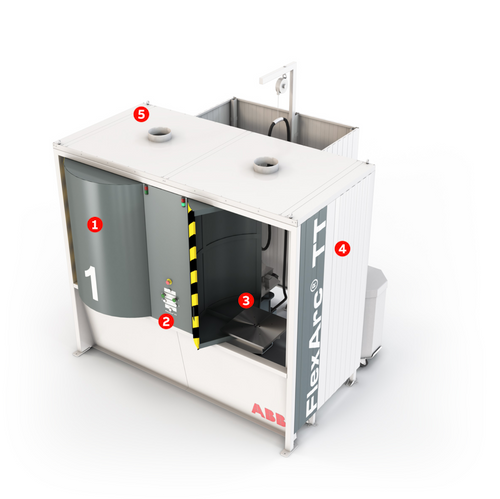

Description

3D Quality Inspection

Measure success with ABB’s latest quality inspection solution. The 3D Quality Inspection system simplifies the measuring on manufactured products. Based on structured light and photogrammetry, 3D Quality Inspection is capable of measuring faults that are less than half the width of a human hair at a pace that is dramatically faster than traditional measuring inspection tools. 3DQI not only offers quick and accurate quality checks, but also reduces expensive rework and scrappage.

Key Features

Unlike traditional measuring machines that use a contact-based method to inspect manufactured products, 3DVM uses a 3D sensor to capture multiple images of the product and compare it to a master CAD model. This contact-less technique allows operators to test for quality at a much faster rate and with more information than traditional tools and manual inspections.

Forging flexibility

The system targets the off-line measuring and quality inspection, while its modularity allows customisation or expansion to meet evolving business needs. All the programming of the robot can be done offline on RobotStudio and sent to the single logic controller that controls the entire robot inspection setup.

-2_1670261595__49352.original.png)