Description

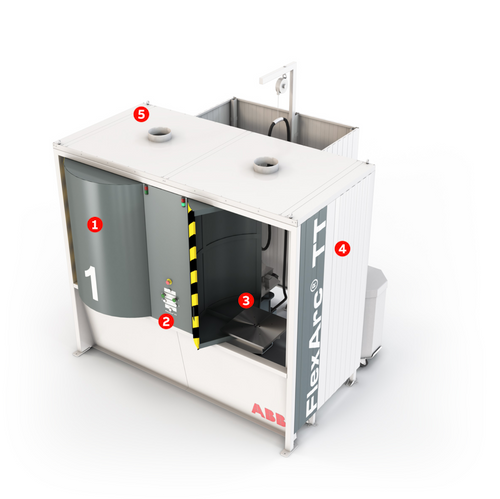

OmniVance FlexArc - Lite B

Twin station solution where the robot works on one side and the operator loads and unloads on the other side. The up to 750 kg load positioner allows you to rotate the workpiece in two axes.

Key Features

Low Entry Cost

An effective way to introduce an automated welding process. An ideal solution for low volume production with a high product mix.

The roofing – fume hood

All FlexArc® Lite models can be equiped with a fume hood above the welding zone. Roofing is used to remove dust and harmful gases generated during the welding process, helping to maintain safe and comfortable workplace conditions.

An effective way to introduce an automated welding process. An ideal solution for low volume production with a high product mix.

The roofing – fume hood

All FlexArc® Lite models can be equiped with a fume hood above the welding zone. Roofing is used to remove dust and harmful gases generated during the welding process, helping to maintain safe and comfortable workplace conditions.

Compact design

FlexArc® Lite cells have been designed not only to achieve the best price/performance ratio, but also to optimize the use of production space. There is even a choice of cell orientation in the right or left version.

Fast Ramp-Up

The Lite cells arrive at the facility ready to weld. The easy-to-learn interface reduces both training and setup time. Workcells are pre-assembled on a common base for quick setup and relocation.

FlexArc® Lite cells have been designed not only to achieve the best price/performance ratio, but also to optimize the use of production space. There is even a choice of cell orientation in the right or left version.

Fast Ramp-Up

The Lite cells arrive at the facility ready to weld. The easy-to-learn interface reduces both training and setup time. Workcells are pre-assembled on a common base for quick setup and relocation.

-2_1670261595__49352.original.png)